CNC Spinning and Turning Machine/ dish end making machine

Standard Configurations

* Siemens 808D as standard CNC system which has USB port.

* Meehanite cast iron after aging treatment, with high quality and less deformation.

* Adopt independent spindle unit to ensure good movement precision, stiffness and stability.

* Precision ball screws ensure dynamic performance well and positioning accurately.

* X-axis adopts integral two-way ball screw, 2 rollers move in synchronization.

* Feeding axles are driven by servo motors.

* Spindle motor is Servo controlled.

* Hydraulic tailstock. Mobile and clamp by hydraulic system.

* Integrated automatic lubrication system makes the maintenance more reliable.

* Configuration cooling pump.

* Mobile manual pulse generator makes easy to operate.

* Semi-enclosed shield.

Purpose of Machine Tool:

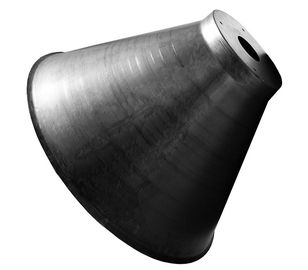

SP series CNC Spinning and Turning Machine (Double Roller) is especially developed to spin kitchenwares, lamps, auto fittings, ventilations and art wares. It has many patents issued by the State Intellectual Property Office. This machine is practical, professional and strong. It has high production efficiency and can complete horn, bucket, cone type, parabolic products. It can also process threading, trimming, flanging and rolling at the same machine tool. The machine can spin many materials such as carbon steel, stainless steel, aluminum and copper etc. It has solved the traditional problems such as lack of skilled workers. With advanced digital control, it is easy to operate. The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for light, automobile, mechanic and other manufacturing industries.

Company:

Wuxi Jinqiu Machinery Co.,ltd. formerly known as Wuxi Metallurgical Machinery Factory, registered trademark for "Jinqiu" brand, was founded in June 1969. It is in Wuxi city, 150 kilometers far from Shanghai city. It mainly produces hydraulic press brake, hydraulic shears, CNC hydraulic punching machine and other series product. It is one of the earliest factory in China to make these metal sheet machines. We have been to stated enterprise, since 2002, we recombined to private company, and got fast development.

| CNC Spinning and Turning Machine |

| Items |

Technical Parameters |

|

| Model |

SP1200 |

|

| Amount of Rollers |

Sync 2+ |

|

| Max. Diameter of Blank |

Φ1200 mm |

|

| Max. Turning Diameter |

Φ800 mm |

|

| Max. Length of Work Piece |

600 mm |

|

| Thickness of Blank |

0.5-7.0 mm ( Aluminum, Copper) 0.5-4.0 mm (Carbon Steel) 0.5-3.0 mm (Stainless Steel) |

|

| X-axis Stroke |

610 mm |

|

| Z-axis Stroke |

780 mm |

|

| X-axis Force |

60 kN |

|

| Z-axis Force |

60 kN |

|

| Tailstock Force |

40 kN |

|

| Guide Rail Type |

Linear Guide Rail |

|

| Width of Bed |

850 mm |

|

| Rapid Traverse X/Z-axis |

8/12 m/min |

|

| Servo Torque X/Z-axis |

23/18 N.m |

|

| Pulse Equivalent X/Z-axis |

0.001 mm |

|

| Positioning Accuracy |

0.015 mm |

|

| Repetitive Positioning Accuracy |

0.008 mm |

|

| Spindle Nose |

C11 |

|

| Spindle Taper |

120(1:20)Metric |

|

| Spindle Bore |

Φ110 mm |

|

| Spindle Speed |

1500 rpm |

|

| Tailstock Stroke |

500 mm |

|

| Stroke of Tailstock Quill |

550 mm |

|

| Diameter of Tailstock Quill |

Φ85 mm |

|

| Amount of Tools / Shank Size |

6+1/30x30 mm² |

|

| Spindle Motor Power |

22 kw |

|

| Hydraulic Power |

4 kw |

|

| Machining Accuracy |

It 6 |

|

| Surface Roughness |

Ra 1.25 |

|

| Service Voltage |

380V AC |

|

| Power Capacity |

30 KVA |

|

| Overall Dimensions |

3.6x2.5x2.4 m³ |

|

| Net Weight |

9500 kg |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!