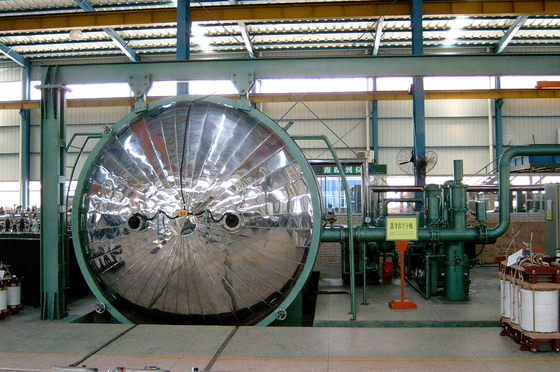

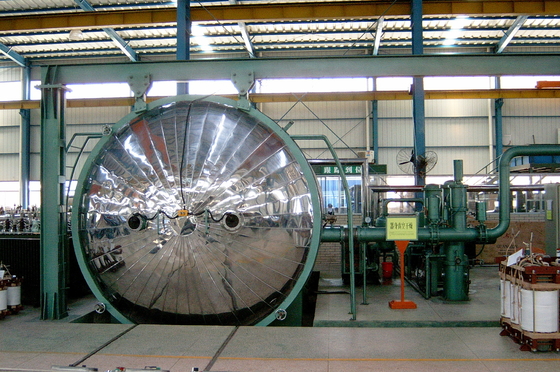

Vacuum drying equipment for transformers

Features:

By adopting the pressure swing drying process, the drying time is reduced by about 30-40% compared to conventional vacuum drying, with reliable performance, high efficiency, and energy saving.

Computer automatic control, achieving true unmanned and fully automatic drying.

The computer automatically performs endpoint judgment, and the judgment results are accurate and reliable.

The heat transfer oil and steam heating method for the inner discharge pipe of the tank are optional.

Door opening methods: electric sliding door, hydraulic flip up door, electric swing door

Tank structure: horizontal square, horizontal circular

The main purpose of the equipment

This equipment is used for the drying treatment of transformers or other electrical products with a voltage level of 35KV and below, and a single unit capacity of 16000KVA and below. Party B guarantees the process and quality requirements of the product treatment, and provides process treatment plans and related control procedures for two voltage levels of 35KV and 10KV.

Technical Proposal

1. Equipment composition

1.1. One set of vacuum drying tank system

1.2. One set of electric door opening system

1.3. One set of electric trolley system

1.4. One set of vacuum system

1.5. One set of low-temperature condensation system

1.6. One set of heating system

1.7 A set of cooling water pipeline system

1.8 One set of pneumatic Plumbing

1.9. One set of control system

2. Equipment power, water, gas source, and basic conditions requirements (provided by the user)

2.1. Rated power: 110kW, 380V, 50Hz, three-phase five wire dedicated distribution cabinet, with power connected to the electrical control cabinet.

2.2. Water source: Pressure>0.1MPa, maximum consumption>3m3/h, water temperature ≤ 25 ℃.

2.3. Compressed air: 0.4~0.6MPa, with a compressed air consumption of approximately 0.3m3/min.

2.4. Equipment footprint: approximately 7000 × 8500mm.

3. Technical conditions of each system

3.1. One set of vacuum drying tank system

Technical indicators:

Tank size Ф 3200× 4000mm, horizontally placed on the ground, with the track inside the tank flush with the ground. The side moving electric door is opened, and when the tank door is closed in place, it is pneumatically locked; The direction of opening the door is to face the tank door and move it electrically to the right side to open.

Extreme vacuum degree (no-load, cold state) ≤ 10Pa, leakage rate (no-load, cold state) ≤ 100Pa · L/S.The tank is heated by a row of Negage pipes. The heat transfer oil is used as the heat transfer medium. The area of the heated row pipes meets the process requirements of the variable pressure method. The heated row pipes are made of seamless steel pipes and arranged on four sides (both sides, bottom and back).

The working temperature is 115 ± 5 ℃, with automatic temperature control. The tank is equipped with three temperature sensors to measure the temperature of the space inside the tank, the temperature of the body, and the insulation material.

The flange sealing ring of the tank body is a high-temperature and oil-resistant sealing ring.

The tank is equipped with a work trolley, with a load capacity of 30T and a size of 2200mmX4000mm.

Rock wool insulation, stainless steel (SUS430) sheet armor

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!