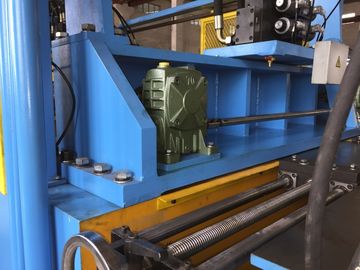

Transformer corrugated tank machine for fin with best quality and middle price

The factory history in Transformer equipments/Machine:

we have been dedicating on development and production of transformer manufacturing equipment since 1984--the earest factory in China,with 120 staffs in this department.The products are widely adopted by customers all over the country and high praised by the users. In the equipment installation and commissioning phase, we can, upon the request of the buyer, send our onsite service force to give local technical instructions, free of charge, and provide training until the operator can skilled run the equipment independently.

Our Products have lasting performance, reliable quality, high efficiency and easy operation. The latest and most practical equipment for producing tranformer of wave-shape oil tank.

BW-1600 Corrugated Band Former Main Technical Parameters

(Remarks: all of the technical parameters as below deviation as no more than 0.2%

- Steel Plate Width:B 300 ~1600mm

2. Steel plate thickness:S 1.0 ~1.5mm

3. Corrugation height :H 50~400mm

4. Corrugation pitch:t ≥40mm

5. Net clearance between corrugations :e 8mm

6. Number of corrugation band sets:n 1~4

7. Corrugation band length :L ≤2000mm

8. Folding height :C 15~300mm

9. Length of box board tips(front gap) :a ≥40mm

10:Length of box board tips(rear gap):b ≥40mm

11: Total power of motors:W 35Kw

12: Total weight: 25500Kg

13: Floor space : 13000×7100mm

14: Equipment running frequency : 50Hz

15 Unroller Max. Bearing weight :12000Kg

16 Feeding lifter Max. Bearing weight:12000Kg

17 Roll Coil inner diameter scope (Axis unrolleris hydraulic Braking open up and shrink) :470~520mm

18 Roll Coil Max. diameter :1200mm

(19) Unroller revolve speed :12rpm

(20) Hydraulic System need equip two individual filter system(Iron or metal filter system and normal material filter system)

(21) Corrugated Band Former need to meet Strength tendon embossing function (include provide related Template)

|

(mm)

(Corrugated plate width)

|

(mm)

(Height)

|

Strength tendon embossing(item) |

| 700~1600 |

≥150

(include every10mm stride distance

|

1 |

|

≥250

(include every10mm stride distance

|

2 |

BW-1600 Corrugated Band Former Electrical and electronic control element supplier list(Domestic configuration)

| NO |

NAME |

SUPPLIER |

| 1 |

valve

|

Beijing huade

|

| 2 |

Electrical components

|

schneider |

| 3 |

PLC, touch screen, frequency converter, servo

|

Xinjie;yineng

|

| 4 |

reducer

|

Hangzhou jiacheng

|

| 5 |

bearing

|

Shanghai bearing co., LTD

|

| 6 |

Oil cylinder

|

Shanghai shield g machinery co., LTD

|

| 7 |

Planetary gear reducer

|

Hubei planetary

|

| 8 |

The motor

|

Jiangsu dazhong

|

| 9 |

Ball screw, linear guide rail

|

Taiwan TBI |

| 10 |

Oil cooler 8p |

Zheyue machinery

|

The warranty period for the machine is one year, and the user enjoys free warranty service within the warranty period. if the machine has failure beyond the warranty period, we will also help the user remove the difficulty and try our best to maintain and repair the machine with our zealously heart. we off lifelong service and spare parts .

Client Satisfaction

Being a clinet focused organization; we make every possible effort to supply products as per our client's desires and expectation. we also provide them customization solution, in which the products are designed and manufacured according to the specified details of our respectable clietele. Our assurance to make timely delivery of the bulk orders has also enable us in estalishing a respectable place in industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!