30 ton 1300mm Hydraulic Press Brake Machine with synchronizing Torsion Bar

Technical Details:

Mode: WC67Y-30/1300

Norminal Press: 30 ton

Length of Table: 1300mm

Distance between Housing: 1020mm

Throat Depth: 200mm

Ram Stroke: 100mm

Ram Speed: 60/10/50 mm/s

Open Height: 210 mm

Main Motor: 3 Kw

Volume of oil tank: 77L

Weight: 1780 kgs

Overall Dimensions: L 1500 mm

W 1080 mm

H 1965 mm

Production Introduction:

1. The steel-welded frame could make sure high strength, hight rigidity and high accuracy

2. Using of mechanical forced synchro system, both sides of sliders move in parallel by synchro axis.

3. Deflection compensation unit is installed in the upper mould, upper mould clamping device is an option.

4. When NC press Brake, X-axis backgauge is driven by servo motor, adoapted ball-screw and linear guide way

5. When NC press brake, ram stroke are controlled by servo motor, it could make sure higher positioning accuracy

Optional for customer:

1. Color: customer can choose to match their existed machines

2. Bending die toolings: the machine has included standard toolings, but we can also specially design according to customers workjobs.

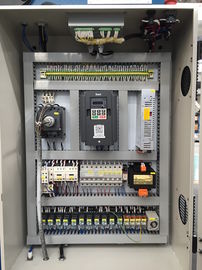

3. Electrical components: we use Schneider brand

4. Bending Thickness: please calculate according to 650x thicknessx thicknessx length/ 8 x thickness, so 30 ton can bend max 3mm with 1300mm length. If shorter, it can bend more thickness.

5. Bending width range: max 1300mm

6. Certificate: CE, CQC, and ISO

7. Bending material: mild steel, stainless steel, aluminum steel

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!