Product Description:

The Hydraulic CNC Sheet Metal Shearer is a state-of-the-art metal plate cutting machine designed to deliver high precision and efficiency in industrial metalworking processes. This advanced piece of equipment integrates hydraulic power with CNC (Computer Numerical Control) technology, making it an indispensable tool for fabricating metal sheets with exact measurements and smooth edges. Its robust design and reliable performance make it ideal for various applications in manufacturing, construction, automotive, and other metalworking industries.

This Automatic CNC Hydraulic Shearing Machine is engineered to handle metal plates with a thickness of up to 16 mm, allowing it to cut through a wide range of materials with ease. The machine is equipped with a substantial blade length of 6200 mm, enabling users to process large sheets of metal in a single operation. This feature significantly increases productivity by reducing the need for multiple cuts and minimizing material waste.

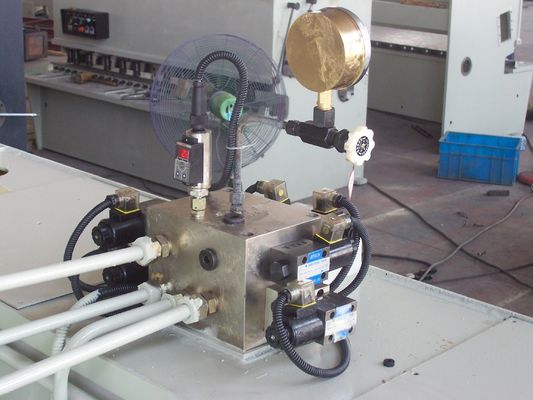

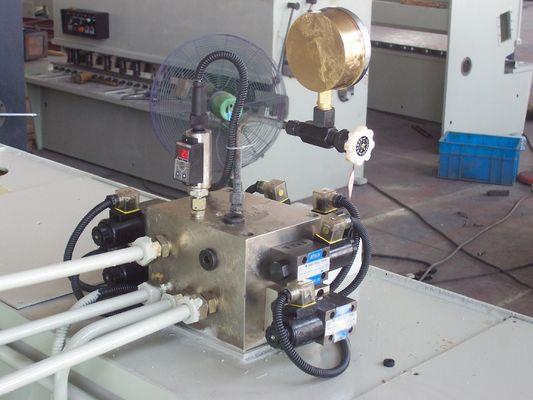

The machine’s power unit is rated at 7.5KW, providing sufficient hydraulic force to ensure smooth and consistent cutting action. This power specification enables the hydraulic system to operate efficiently, maintaining optimal pressure to achieve precise shearing results. The combination of hydraulic power and CNC control ensures that each cut is accurate, repeatable, and clean, which is critical for maintaining the quality standards required in modern metal fabrication.

One of the notable features of this Precision CNC Hydraulic Shearing Equipment is its versatility in handling different sizes and types of metal sheets. The machine weight varies from 2000 kg to 10000 kg, depending on the specific model and configuration chosen. This range allows customers to select a machine that best fits their operational needs, whether for light-duty or heavy-duty cutting tasks. The heavier models provide enhanced stability and durability, which is essential for processing thicker and tougher materials.

The CNC control system incorporated in this shearing machine allows operators to program cutting sequences and dimensions with ease. This automation reduces human error and increases operational efficiency by enabling quick adjustments and consistent production runs. The user-friendly interface ensures that even operators with limited experience can quickly learn to operate the machine and optimize its performance.

In addition to its cutting capabilities, the Hydraulic CNC Sheet Metal Shearer is designed with safety and maintenance in mind. The hydraulic system is equipped with protective measures to prevent overload and ensure smooth operation, while the machine structure is built to withstand the rigors of industrial environments. Regular maintenance is simplified through easy access to key components, helping to minimize downtime and extend the machine’s service life.

Overall, the Automatic CNC Hydraulic Shearing Machine represents a perfect blend of power, precision, and automation. It is an excellent investment for businesses seeking to improve their metal cutting processes, reduce material waste, and enhance production efficiency. Whether cutting steel, aluminum, or other metal sheets, this Precision CNC Hydraulic Shearing Equipment delivers consistent results that meet the highest industry standards.

Features:

-

Product Name: CNC Hydraulic Shearing Machine

-

Type: Sheet Metal Guillotine Shearing Machine

-

Valve Brand: Rexroth for reliable hydraulic control

-

Backgauge Size: 600 mm for precise sheet positioning

-

Machine Weight: Varies from 2000 kg to 10000 kg depending on model

-

Total Weight: 8500 kgs

-

Advanced Hydraulic CNC Sheet Metal Shearer technology for efficient cutting

-

Equipped with Computer Numerical Control for high accuracy and repeatability

-

Robust and durable design suitable for heavy-duty shearing tasks

-

Ideal for a wide range of sheet metal shearing applications

-

Hydraulic CNC Sheet Metal Shearer ensures smooth and precise operation

Technical Parameters:

|

Backgauge

|

600 Mm

|

|

Year

|

2019

|

|

Blade Length

|

6200 Mm

|

|

Power

|

7.5KW

|

|

Application

|

Metal Plate Cutting Machine

|

|

Material

|

Q235 Or Q345 Mild Steel

|

|

Blade Material

|

High-speed Steel Or Alloy Steel

|

|

Keyword

|

Hydrualic Shearing Machine

|

|

Function

|

Cutting Mild Steel / stainless Steel

|

|

Machine Weight

|

Varies From 2000kg To 10000kg

|

Applications:

The Precision CNC Hydraulic Shearing Equipment is an essential tool for industries requiring accurate and efficient cutting of mild steel and stainless steel materials. Designed to handle materials such as Q235 or Q345 mild steel, this advanced Computer Numerical Control Hydraulic Shearing Machine offers exceptional performance and reliability. With a powerful 7.5KW motor and an impressive blade length of 6200 mm, it ensures seamless cutting operations for various manufacturing and fabrication needs.

This CNC Hydraulic Metal Shearing Machine finds its application in numerous industrial occasions and scenarios. It is widely used in metal fabrication workshops where precise cutting of large steel sheets is required. The machine’s high precision and automated control make it ideal for producing components that demand tight tolerances and clean edges. Its ability to cut both mild steel and stainless steel materials expands its usability across automotive manufacturing, shipbuilding, aerospace, and construction sectors.

In manufacturing plants, the CNC Hydraulic Shearing Machine excels in cutting steel plates that are then used for the production of machinery parts, structural elements, and equipment enclosures. The computer numerical control system allows operators to program cutting patterns with minimal error, significantly increasing productivity and reducing material waste. This makes it suitable for batch production environments and custom metalworking projects alike.

Additionally, the machine is perfect for repair and maintenance workshops where quick and accurate metal cutting is critical for producing replacement parts. The hydraulic shearing mechanism ensures smooth and consistent cutting force, improving the quality of the cut and extending blade life. The blade length of 6200 mm enables the processing of large steel sheets in one go, which is particularly beneficial for large-scale projects.

Overall, this Precision CNC Hydraulic Shearing Equipment is indispensable in any scenario that demands high precision, efficiency, and versatility in cutting mild steel and stainless steel. Its robust design, combined with advanced CNC control, positions it as a top choice for industries aiming to enhance their metal cutting capabilities with a reliable and powerful 7.5KW Computer Numerical Control Hydraulic Shearing Machine.

Customization:

Our CNC Hydraulic Metal Shearing Machine offers customizable options to meet your specific cutting needs. The machine is designed to handle a thickness of up to 16 mm, ensuring precise and efficient shearing of metal sheets. Equipped with a high-quality Rexroth valve, it guarantees smooth and reliable hydraulic performance for consistent operation.

The backgauge can be customized to a length of 600 mm, allowing for accurate positioning and repeatability during the shearing process. With a robust weight of 8500 kgs, the CNC Hydraulic Metal Shearing Machine provides stability and durability for heavy-duty industrial applications.

For blade material, you have the option to choose between high-speed steel or alloy steel blades, both designed to offer excellent cutting performance and long service life. These customization services ensure that the CNC Hydraulic Metal Shearing Machine is tailored to your production requirements, delivering optimal results every time.

Support and Services:

Our CNC Hydraulic Shearing Machine is designed to provide precision cutting with high efficiency and reliability. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services tailored to your needs.

Our technical support team is available to assist you with installation guidance, operation training, troubleshooting, and maintenance advice. We provide detailed user manuals and programming instructions to help you maximize the capabilities of your CNC Hydraulic Shearing Machine.

Regular maintenance services are recommended to keep your machine running smoothly. These services include hydraulic system checks, blade inspections and replacements, lubrication of moving parts, and software updates. Our certified technicians are equipped to perform routine maintenance as well as complex repairs.

In addition to maintenance, we offer customization and upgrade services to enhance the functionality of your shearing machine. This includes software enhancements, integration with other manufacturing systems, and hardware modifications to meet specific production requirements.

We are committed to providing prompt and effective support to minimize downtime. Our after-sales service ensures that any issues are addressed quickly, with genuine spare parts and expert repairs to maintain the integrity of your CNC Hydraulic Shearing Machine.

For optimal use, we recommend following the operational guidelines and safety instructions provided with the machine. Proper training for operators will help prevent accidents and extend the service life of the equipment.

Packing and Shipping:

The CNC Hydraulic Shearing Machine is carefully packaged to ensure safe and secure delivery. It is wrapped with protective materials such as foam and plastic to prevent any damage during transportation. The machine is then placed inside a sturdy wooden crate that is reinforced to withstand handling and shipping stresses.

For shipping, the wooden crate is securely fastened to pallets to facilitate easy loading and unloading. The packaging is designed to protect the machine from moisture, dust, and mechanical impact. All necessary precautions are taken to comply with international shipping standards, ensuring that the CNC Hydraulic Shearing Machine arrives in perfect condition at its destination.

FAQ:

Q1: What materials can the CNC Hydraulic Shearing Machine cut?

A1: The CNC Hydraulic Shearing Machine is capable of cutting various metal sheets including mild steel, stainless steel, aluminum, and other metal alloys with high precision.

Q2: What is the maximum cutting thickness and length of this machine?

A2: This machine can shear metal sheets up to 20mm in thickness and a maximum length of 3000mm, depending on the specific model configuration.

Q3: How does the CNC control system improve the shearing process?

A3: The CNC control system allows for accurate programming of cutting angles, lengths, and patterns, which enhances precision, reduces material waste, and improves overall efficiency.

Q4: What safety features are included in the CNC Hydraulic Shearing Machine?

A4: The machine is equipped with safety guards, emergency stop buttons, and overload protection to ensure operator safety during operation.

Q5: How is maintenance performed on the CNC Hydraulic Shearing Machine?

A5: Regular maintenance includes checking hydraulic oil levels, inspecting blades for wear, lubricating moving parts, and ensuring the CNC system is updated and calibrated for optimal performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!