Fin simple drawing, it will be in 8 rows ( but in straight line or dislocation line will be confirmed after discuss. And all sizes also need to be confirmed later)

The final drawing, after 30% down payment, we will give to customer for confirmation, after confirm, please sign and stamp on the drawing, our machine will start to produce according to fin designs.

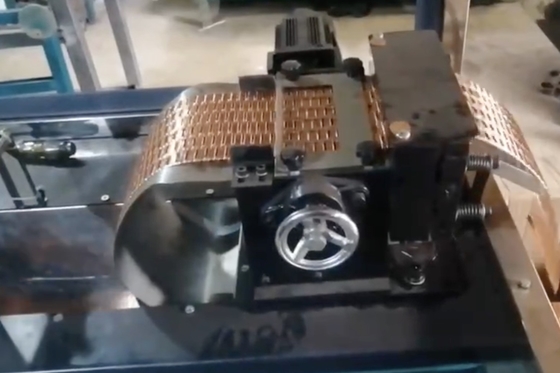

Rolling machine

Technical parameters:

1. Applicable material of rolling fin: suitable for production of copper flat fin

2. Number of rolling sheet rows: 2-8 rows

3. Thickness of rolling sheet: 0.06-0.08 mm copper sheet

4. Finished rolling plate type: with cooling hole+pipe hole, see the drawing for details

5. Rolling speed: 200/300 rpm

6. Cutting: automatic

7. Feeding: automatic

8. Motor power: 1 5 KW

9. Control mode: potentiometer, variable frequency motor, with adjustable speed, light-controlled counting and automatic cut-off

10. Overall dimension of the machine: 1.6 * 0.6 * 1.3 meters

11. Machine weight: 500kgs

To press each fine together into the tubes.

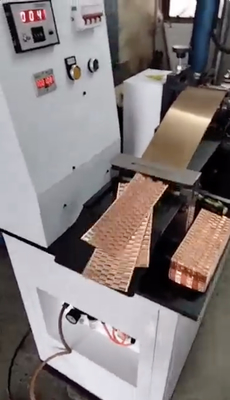

Fin assemble machine

Technical parameters:

1. Applicable fins: 2-8 rows of fins, 7-11 fins per inch, the size of radiator core after threading is 155 mm high and 155 mm wide

2. Fin thickness range of wearable fin: 0.006-0.08mm copper fin

3. The height range of the radiator core that can be pierced: 1.7 meters (according to the requirements)

4. Width range of radiator core that can be pierced: 1.6m (as required)

5. Control mode: computer

6. Motor power: equipped with 5.5kw servo motor, drive, computer touch screen, plc and other electrical appliances

7. Overall dimension of the machine: 1 * 1 * 2.8 meters

8. Machine weight: 500 kgs

Punching head die:

- One single punching : max 36 holes. If need more, then the same as video, the worker push the plate to punch more

- The die design is for: 0.75-1.5 mm thickness brass

- The punching die to punch headers for 2 to 8 rows. Headers drawing with distribution of tubes like below drawing of fins .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!